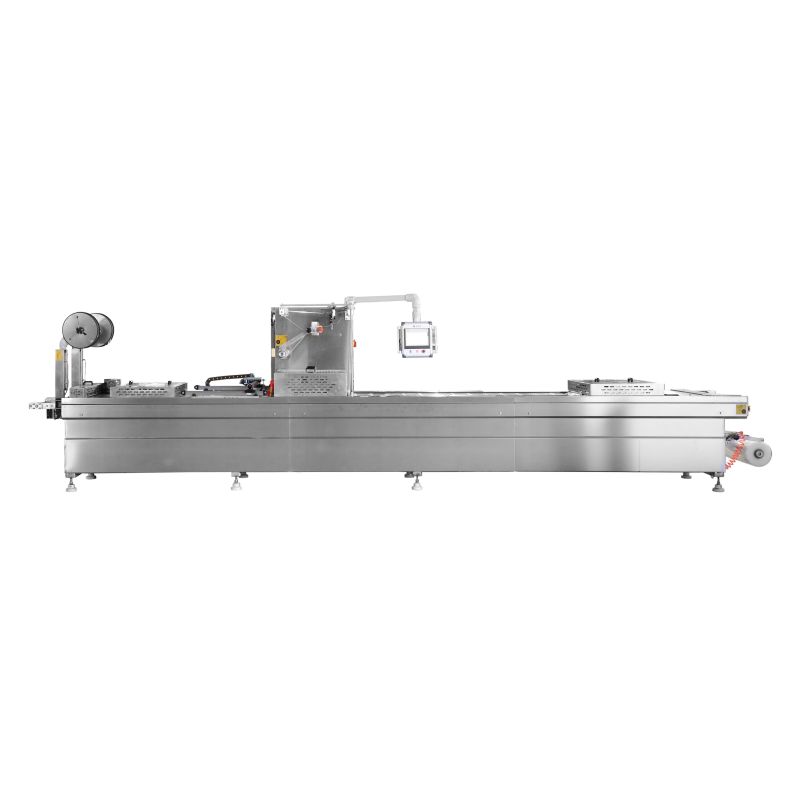

The Automatic Thermoforming Stretch Film Vacuum Packaging Machine is a new generation of vacuum packaging machine developed on the basis of ordinary vacuum packaging machines. It can process the stretch film into a shape suitable for food product and attach it with a composite film. After vacuuming, then sealing and finally divided into independent products. Our company has introduced advanced foreign technology to research and develop a fully automatic continuous stretch soft and hard box vacuum inflatable packaging machine, which completely replaces imported one. The design concept of the fully automatic stretch film packaging machine is: humanization, intelligence, safety and energy saving.

Warranty & Package

Warranty: 24 months from B/L date

Package: International Standard Veneer Case

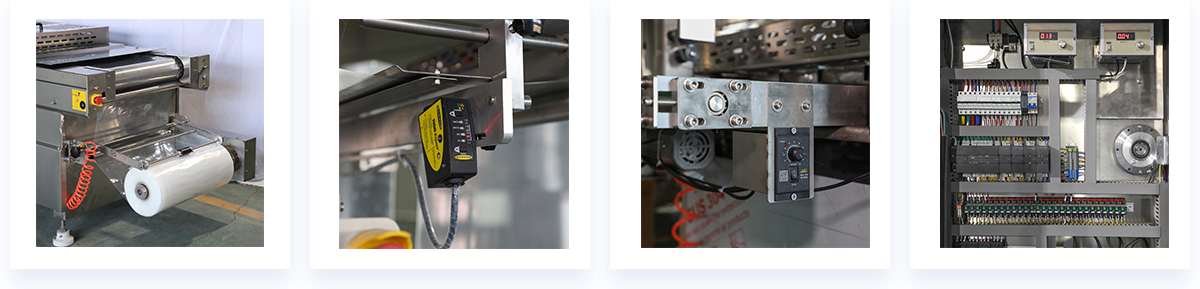

Controlling System

1. Adopt German Siemens PLC.

2. German Siemens true color man-machine interface touch screen with push-pull type design.

3. German Siemens servo system control, high-speed and high-precision servo speed, to ensure beautiful film forming and heat sealing during the production process.

4. Using Taiwan original TYC chain, AirTAC cylinder and solenoid valve to ensure precise mechanical coordination.

5. Using Siemens series low-voltage electrical appliances, equipped with complete safety protection measures, enables the machine to work continuously, and improves the stability and service life.

6. The electrical control box and the servo motor are installed separately, and the signal is not disturbed when the machine is working, ensuring the normal operation of the machine.

Main Functions

1. According to the product packaging needs of different customers, special mold production can be customized, and a variety of products can be produced with one machine.

2. The equipment is equipped with a safety automatic protection system to prevent hidden dangers caused by mis operation or illegal operations by operators, and to prevent safety accidents.

3. All key parts adopt a maintenance-free system and imported oil-free lubrication transmission, so that the machine does not need to be refueled during the normal production process to ensure that the packaged products are pollution-free.

4. The positioning of the photoelectric eye of the printing film and the adjustment function enable the user and the packaging film printing manufacturer to avoid size deviations and economic losses when printing the film.

Advanced Technology

1. The main body of the machine is all made of SUS304 stainless steel, alloy aluminum, and high-strength polymer engineering materials. The design is ingenious to improve the strength, corrosion resistance, acid and alkali resistance and stability of the machine body.

2. The lifting mechanism introduces German technology, the lifting speed is uniform, stable, balanced, the failure rate is extremely low, and the quality stability of the machine itself is improved.

3. Slitting knife system, the overall cutter has been customized according to the user's product. When making different products, it is easy to replace, no safety hazards, and only 30 seconds.

4. The cross-cutting knife system adopts hidden cutting knives to ensure the safety of the machine during the working process.

5. Waste recycling system, energy saving, no noise, simple disassembly and assembly, and improve the operating efficiency of personnel.

6. Pneumatic control execution system; advanced pneumatic drive components, improve equipment wear and tear, prolong machine service life, sensitive response, reduce overall machine maintenance and operating costs, and improve work efficiency.

7. In terms of automation, intelligence and energy saving: summarizing and analyzing the needs of various domestic food industries, making improvements from packaging costs, labor costs, and electricity costs. The operation is simple, convenient and easy to understand, fast speed, low energy consumption, far ahead of the domestic industry level.

8. Safety: The whole machine is equipped with different parts of the safety alarm device, and at the same time, the humanized design of each safety point can avoid the hidden dangers caused by personnel misoperation and other problems.

9. One machine can use multiple molds and different stepping molds, that is, it can make a variety of products and products with different types of packaging. It is simple and convenient to replace the packaging film and molds, and the speed is fast.

● Industrial computer automatic control: control the forming and heat-sealing temperature, forming and heat-sealing time, and vacuum pressure.

● Intelligent safety protection.

● Intelligent colorful film and light film recognition.

● Intelligent film bias and film pre-tightening.

● The working room rises and falls steadily, and the position is accurate to the micron level.

● Smart corner waste film collection, energy saving and environmental protection.

● Ingenuity everywhere, easy for maintenance and repairing.

● Applicable items: various relatively regular foods, meat products, seafood, chilled meat, eggs, snack foods, etc.

| Model | ATP-520 |

| Vacuum Degree (pa) | <=200 |

| No. of Steps (times) | 5-7/min |

| Forming Time (s) | 1-2 |

| Heat Seal Time (s) | 1.5-2.5 |

| Material | SUS304 |

| Vacuum Pump | German Busch (optional) |

| Forming/Sealing Pressure | 0.15MPa/0.15-0.3MPa |

| Forming/Sealing Temperature | 70-120℃ / 125-150℃ |

| Width of Upper/Lower film | 496mm / 522mm |

| Compressed Air Pressure | ≥0.6MPa |

| Cooling Water Pressure | ≥0.1MPa |

| Electrical | 380V 3Ph 50Hz |

| Power | Max. 15KW |

| Dimensions (LxWxH mm) | 8800x1100x2000 |

| Machine Weight(kg) | 1900 (Approx.) |